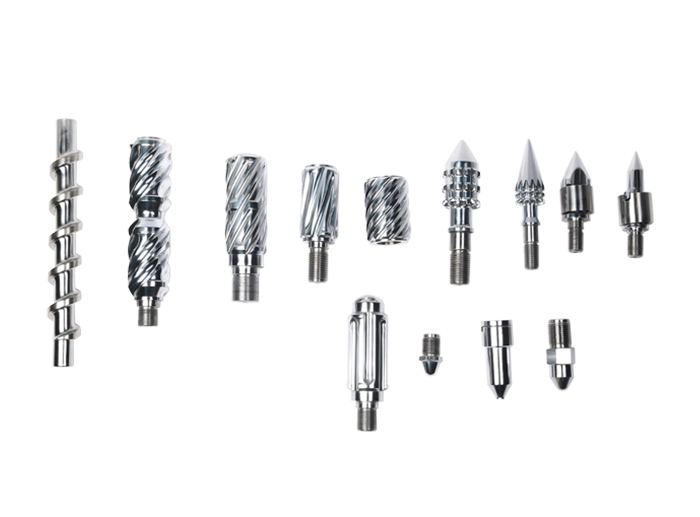

Nozzle + front + screw head

Material High quality he different Alloy Steel of High Quality 1) 38CrMoAIA (JIS sacm645) 2) 42CrMo ...

Screw heads may seem like a small detail, but they play […]

Screw heads may seem like a small detail, but they play a crucial role in many aspects of construction, engineering, and DIY projects. Different types of screw heads are designed to serve specific purposes, and understanding the differences can help you choose the right screws for your specific project needs. Here is an overview of some common types of screw heads and their uses.

Flat Head

A flat head screw is the most common type of screw head. It has a flat top that allows it to sit flush with the surface it's being screwed into. This makes it ideal for use in applications where a flush surface is necessary, such as attaching hardware to walls or furniture.

Pan Head

A pan head screw has a rounded top with a flat base, making it ideal for use in applications where a smooth surface is necessary. This screw head is often used in sheet metal applications, such as attaching ductwork or securing electronics.

Round Head

A round head screw has a cylindrical shape and a flat top with no angled sides. This type of screw head is often used in woodworking applications where a hole is pre-drilled, allowing the screw head to sink into the wood without damage.

Phillips Head

A Phillips head screw is easily recognizable by its cross-shaped indentation on the top of the screw head. It's designed to fit into a Phillips-head screwdriver, which makes it easy to install and remove. This screw head type is commonly used in a range of applications, from DIY projects to industrial manufacturing.

Hex Head

A hex head screw has a hexagonal shape on the top of the screw head. This type of screw head is ideal for use in applications where a high torque is required, such as with heavy machinery or construction projects.

Torx Head

A Torx head screw has a six-point star shape on the top of the screw head, which requires a Torx screwdriver to install and remove. This type of screw head provides a high level of torque, making it ideal for use in automotive and electronics applications.

In conclusion, understanding the different types of screw heads and their uses is essential for choosing the right screws for your specific project needs. By considering the type of material you're working with, the level of torque required, and the desired finished surface, you can choose the right screw head type to ensure a successful and secure installation. So the next time you're working on a project, remember to consider the screw head and choose the right one for the job at hand.