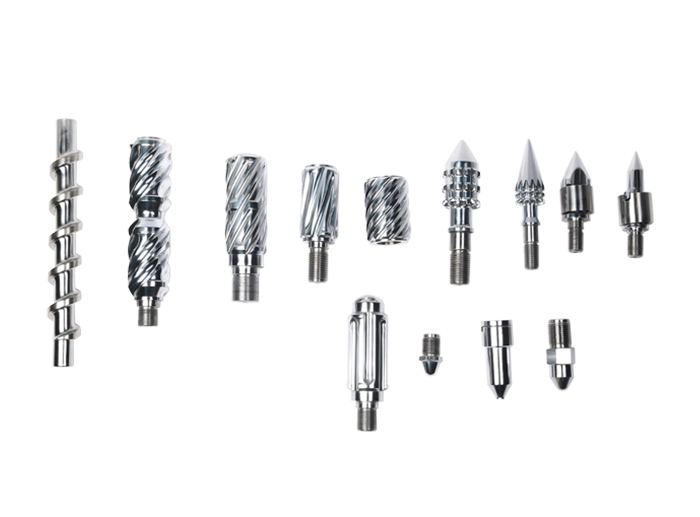

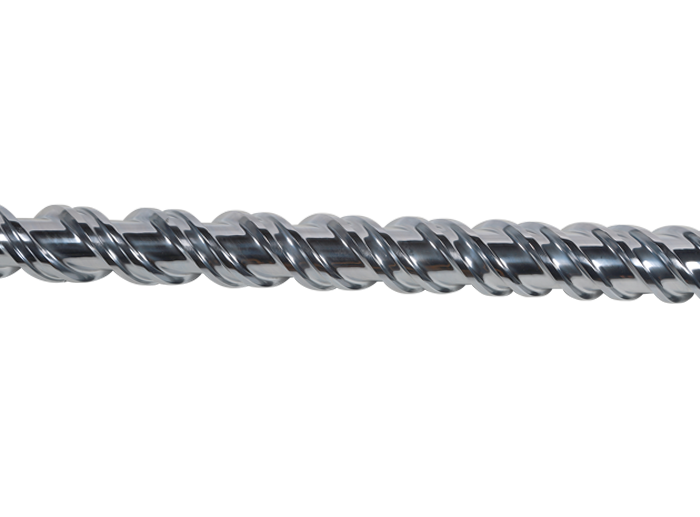

Established in 1989, Zhejiang Jinxing Injection Screws Manufacture Co., Ltd is a professional Parallel twin screws and cylinders manufacturers and Parallel twin screws and cylinders suppliers, through more than 30 years development already has a good reputation in the industry, Located in “China Screw Center ”, the company is one of the top screws and barrels manufacturers in China and continuously improving and expanding, which boast many professional equipments such as CNC whirl-wind milling PICK UP 500 from Austria, CNC turning center, CNC polishing machine, full-auto plasma welding machine, coordinate measuring machine (CMM), CNC grinding machine, CNC screw milling machine, CNC vertical honing machine, CNC screw milling machine, CNC machine center, Tempering furnace, Pit-type nitriding furnace, cylindrical grinder and 10 meter boring milling machine, etc. We established P&C Lab and introduced advanced inspection equipment and method to check the quality of the products. Inspection includes nitriding thickness, property, metallographic analysis, hardness, torque, tension, straightness, roughness, etc. Here we can offer you the various screws and barrels exactly as you want. You can also trust our rich experiences in the advanced technology and our premium service.